Our electronic and software expertise

45 years of expertise in electronic design

Maatel has always aimed to increase its expertise and gain more experience in its core activity: electronic engineering.

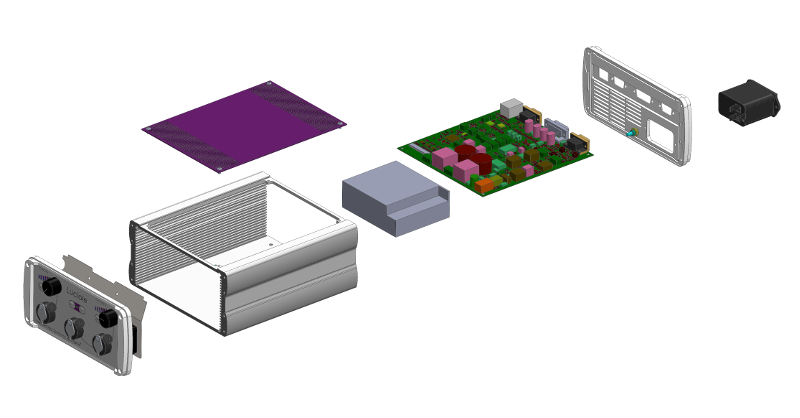

Maatel provides services in digital and analog electronics and power electronics.

Screen

Touchscreen interface

Contactless detection

etc…

Sensor processing

Power supply

LLC resonance

DC/DC

AC/DC

Motor control

DC

Brushless

Stepper

Profibus, Profinet

EtherIP, EtherCat

SIGFOX, LORA

USB, WIFI, Ethernet, Bluetooth,

ZIGBEE, RFID, GPRS, GSM,

2G, 3G, 4G, Irda, CAN

A dedicated circuit team

Because we design for production, the in-house production of electronic circuit boards allows us to anticipate the product industrialization phase and offer greater design flexibility.

This in-house expertise means we can provide optimized reactivity when changing a design. For example, for new dimensions, a new environmental constraint, or a new component: our in-house team simply modifies the board’s circuit.

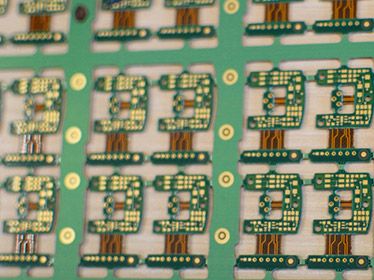

As well as traditional circuits such as simple rigid one-sided and multi-level boards, our teams are trained and have significant experience in the design and production of new technology for more complex circuit boards such as flex and rigid-flex.

FLEX circuit boards are completely flexible circuit boards. They are also known as flexible printed circuit boards, Flex PCB or Flex circuit.

We have already designed and manufactured FLEX circuit boards, for example for Mindmaze’s NeuroGoggles® , where the flexible circuit board is installed directly into the headset.

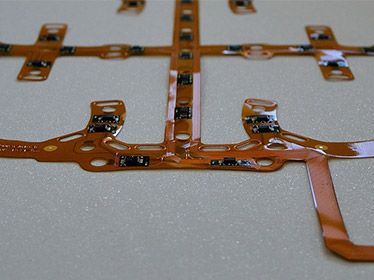

Rigid-Flex circuit boards, also known as mixed or semi-rigid boards, combine Flex technology and rigid boards, one-sided or multi-layered. This mix allows for the circuit board to be bent to enter a confined space.

This approach is useful for the optimization of mass production processes. Instead of producing several circuit boards then linking them together, only one circuit board is mass produced, ready to be put in the final product.

Maatel designs and mass produces this type of board, particularly for mobile medical devices, i.e. devices worn by patients.

Our teams are also familiar with controlled impedance technology, Fine Pitch and BGA up to step 1.4 (Ball Grid Array).

We use PADS and CADSTAR CAD systems for routing circuit boards.

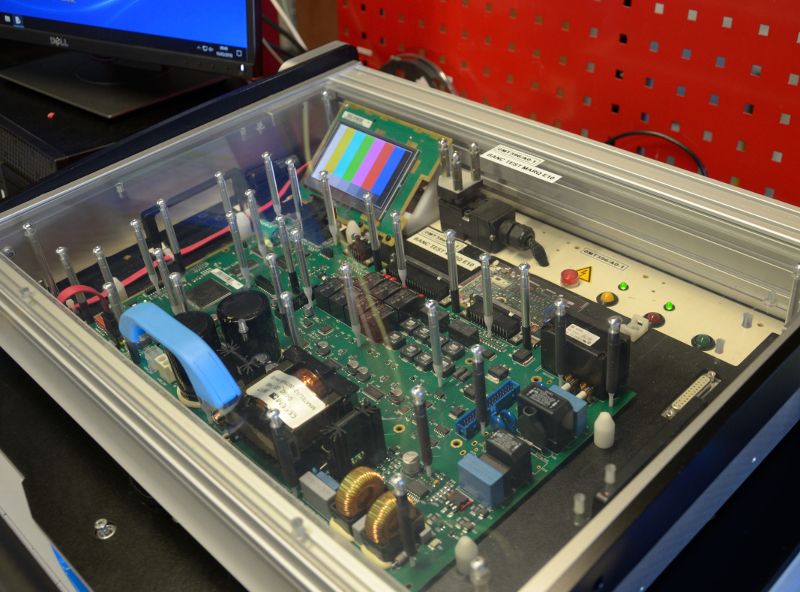

Designing test tools

At Maatel, we have in-house autonomous testing facilities: our teams design them to personally tool/bench test your products.

This means we can provide significant flexibility to include products in the production chain and exploit our in-house expertise, ensuring contained lead time and an optimized process.

Quality is our priority

From the design phase

The design of your product follows a Project Management Plan (PMP). Based on the specifications we have prepared together, the PMP features all the key information, defines and identifies the main phases of the project, and presents the tasks and role distribution.

Design evolution is recorded in a strict version procedure in order to have a trace of the product’s creation. Versioning is critical for the development of medical devices, but also for certain industrial sectors with high safety standards, such as aviation.

Throughout production

Electrostatic (ESD) risk control

The entire assembly zone is adapted to containing electrostatic effects and meets EPA (Electrostatic Protected Area) standards. Employees are aware of the electrostatic effects, and entry to the production zone is controlled.

Intelligent input-output flow

Maatel has created an input-output flow that guarantees the traceability of raw material batches through to the finished product, optimization of moving electronic components, and risk containment due to storage and handling.