Our full-range service

Comprehensive service

Maatel provides a comprehensive service – from design, through product completion to mass production:

Initial project management

Analysing the needs and risks of your project

Using our experience acquired over 48 years, we analyse your development criteria with you, then propose technical solutions and identify the phases required by your project together:

YOUR REQUIREMENTS

Product specifications

Goals

Deadlines

Quantity

Quality

PRODUCT RISKS

Assess and list product risks collated in a criticality matrix

ISO 9001 and 13 485

Establishing PRODUCT SPECIFICATIONS

Analyzing feasibility for industrial requirements and standard compliance

Our goal is to provide you with real solutions for a real product: using their extensive skills and expertise, our teams anticipate the product industrialization stage and standard compliance requirements for your product.

This is a key phase in the launch of a project, and essential for planning your product’s time to market.

A controlled quality control system

We are particularly attentive to the quality control of your project to ensure successful production and future sales. A Project Management Plan (PMP), the cornerstone for monitoring your project, is developed from the product specification. The PMP features the following elements:

GOAL

CUSTOMER DOCUMENTATION

Models, product specifications etc.

SUB-CONTRACTOR MANAGEMENT

CRITICALITY MATRIX

PROJECT MACRO-PLANNING

TEAM

DIALOGUE PROCESS

TECHNICAL REQUIREMENTS

Architecture documentation specifications, detailed design

Product design

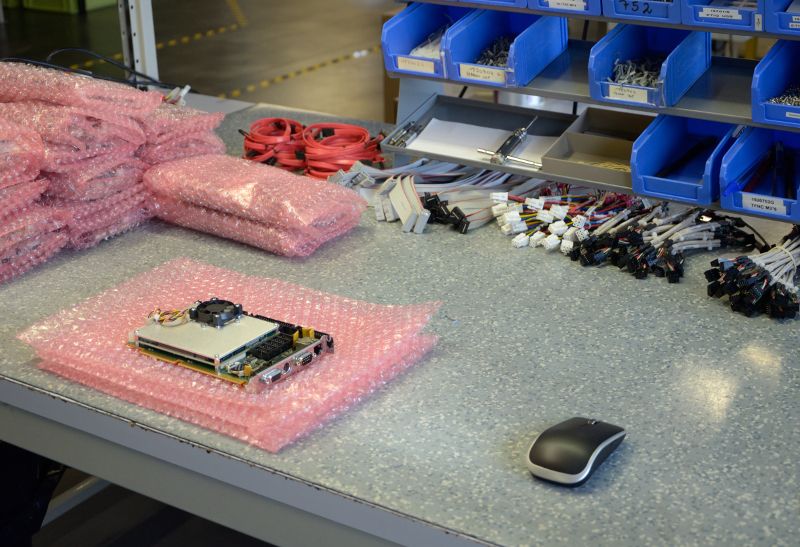

Qualified expertise for designing your product

Thanks to a research team of 30, Maatel has very varied skills and experience in-house, allowing for the assignment of specific talents suited to your design project.

Using the project specifications, and led by the project manager, our teams develop the software and hardware.

In-house tools for software design and routing circuit boards

A dedicated contact responsible for your project

A multidisciplinary team: electronics, software and mechanical skills.

A research team of 25

A truly industrial perspective: Design For excellence

Because we lead your project right through to mass production, our teams are particularly attentive to the industrialization requirements of your electronic product, using standard Design for eXcellence tools:

Procurement

Manufacturing

Assembly

Cost

Test

When you trust us with your project from the outset, you can be sure the design phase carefully prepares for future product industrialization: much more than a functional prototype, you have a prototype prepared for production and sale, ensuring optimal and contained time to market.

Design approval

A key step before product industrialization, design approval requires a series of prototype tests.

Functional tests are carried out according to an approval plan of material conception:

Prototype Approval in field conditions

Approving device functions

Environmental impact: e.g. the electromagnetic effects of other electronic equipment (CEM tests)

A thorough functional study

Signal, temperature, functions, timing analysis etc.

Extreme environmental conditions testing: e.g. product wear tests in a controlled climate chamber

Product industrialization & transfer to production

CREATING PRODUCTION RECORDS

LAUNCHING THE PRODUCTION PROCESS

Approving industrial partners

Approving the finished product process: workstation evaluation, layout, handling, storage and training

APPROVAL OF THE PROCESS VIA SEVERAL TEST SERIES

Mass production

Supply management

We anticipate the supply chain

Maatel strategy is to develop the product while anticipating the industrial production. All the supply chain is anticipated from the model stage: based on product specifications, a collaborative reflexion is started by the research team, involving procurement and logistics teams.

ANTICIPATION

Component supply and availability

Prices

Component obsolescence status

WELL-INFORMED DEVELOPMENT CHOICES

OPTIMIZED PRODUCTION

Controlled and optimized costs

Safe procurement

Mass production and small volume production

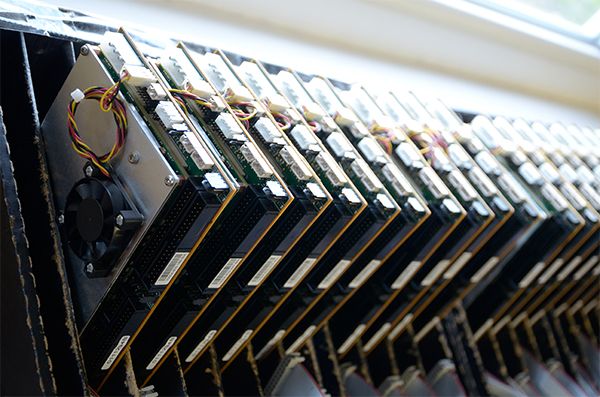

Controlled mass production

Thanks to our production model, we can propose very competitive prices with extensive flexibility for mass production of electronic products:

Supply of electronic components by Maatel

Outsourcing board brazing

Circuit boards (PCBA) tested on arrival

Integration in the final product

Test cycle of the finished product before delivery to the customer

Our production process includes a quality control system including:

– Intelligent input-output flow

– Electrostatic (ESD) risk control

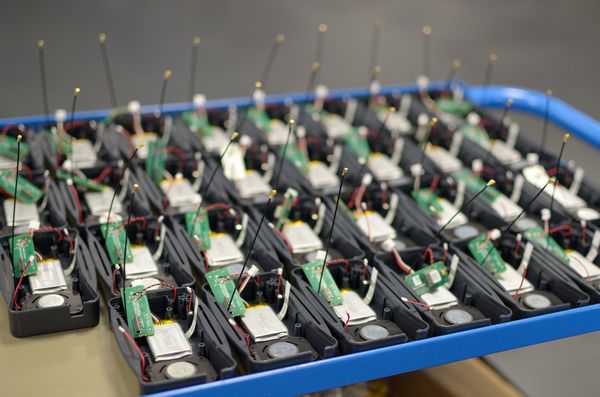

The “Fab’étude”: small volume production

At Maatel, we have a department dedicated to trial products and small volume production to provide a reactive service. The “Fab’étude” department has a quality control system identical to the mass production quality system and specifically created for multiple simultaneous projects.

Product Life Management

Technology monitoring

For your competitive lead, it is vital to ensure your product is at the cutting edge of technology and meets all your customers’ latest requirements and uses.

Maatel carries out constant technology monitoring relative to your products and their environment to ensure you keep the competitive edge. A twofold goal:

– Ensure you stay ahead in the technological race

– Detect new technology and components to reduce production costs and improve product reliability.

Technology monitoring is essential given the increasingly stringent requirements for connectivity in your devices. To this end, Maatel strives to be ahead in technological progress via our commitment to the Serene IoT European collaborative project.

Managing obsolescence

As a manufacturer, Maatel must ensure the longevity of your products.

When obsolescence is identified, we find solutions with you:

Storing components

to ensure the production of your products for a defined period and to avoid any immediate revision of product design.

Finding equivalents:

our network of suppliers, procurement department and R&D department search for similar components to ensure performance levels are maintained and costs contained in the event of changes to the production process for series and trials.

Product design evolution:

Maatel keeps all your original records on file; if no equivalent component meets the requirements, we can propose a re-design of your product within a short lead time.

Effective after-sales service

Malfunctioning medical devices in the hospital have a negative impact on the department’s capacity to treat patients. In the industrial sector, malfunctioning equipment stops production lines. Any type of breakdown requires extreme reactivity. Maatel makes a contractual commitment to repairing your products with high reactivity.

This after-sales reactivity is guarantee by:

Storage of components for your devices to ensure immediate availability.

Our [Fab’étude] department provides the necessary flexibility for prompt repairs.

We keep your records on file to have the expertise at hand that is applicable to the design and tests of your products.

Our sales-service tracks all repairs of your equipment to ensure quality control for their continued operation.